Table of Contents

Introduction.

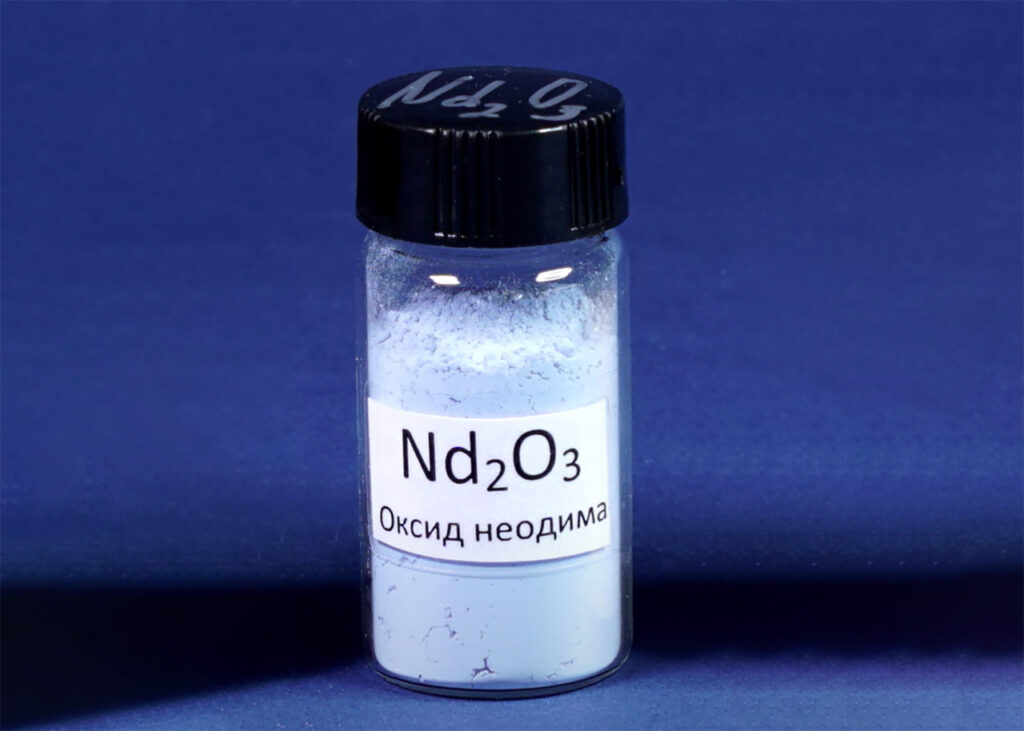

Neodymium Oxide, with the chemical formula Nd2O3, stands as a foundation product in the field of Rare Earth elements. It is a highly critical substance that makes it possible for a lot of our most sophisticated modern technologies. This light grayish-blue powder functions as a critical forerunner for a wide range of industrial products, from effective magnets to innovative optical lenses. As international need for high-performance materials grows, understanding tjhe homes and supply chain of Neodymium Oxide Powder ends up being essential. In this this context, the duty of China Neodymium Oxide producers is crucial, as they command a substantial share of the global market for both raw material removal and high-purity refining. This short article discovers the fundamental characteristics of Nd2O3, its production, its diverse applications, and the dynamics of sourcing this crucial substance.

Core Chemical and Physical Characteristics.

Neodymium Oxide possesses a distinct set of residential properties that make it very useful. Its chemical formula is ND2O3, showing a compound of 2 neodymium atoms and three oxygen atoms. At area temperature, it commonly exists in a hexagonal A-type crystal framework. This framework adds to its high thermal stability, with a melting point going beyond 2,200 ° C.

Visually, high-purity Neodymium Oxide Powder presents as a fine, light grayish-blue or sometimes lilac-colored powder. The exact color can vary slightly depending on pureness levels and particle dimension. An essential chemical property is its solubility. Nd2O3 is insoluble in water. However, it readily dissolves in strong mineral acids, such as hydrochloric acid (HCl) or sulfuric acid (H2SO4), to form corresponding neodymium salts (e.g., NdCl3). This reactivity with acid is essential to a lot of its downstream handling enter other forms, like neodymium metal.

From Ore to High-Purity Powder.

The trip from raw earth to refined Neodymium Oxide Powder is a complicated, multi-stage procedure. Manufacturers largely extract neodymium from 2 major mineral ores: monazite and bastnäsite. These ores contain a mix of various rare earth elements that should be very carefully separated.

The process begins with mining the ore, followed by squashing and grinding it into a fine powder. Next, a sophisticated chemical process known as solvent removal divides the individual rare earth components from each other. This strategy leverages the various chemical fondness of each rare earth element to separate a focused neodymium solution. Once devided, this service is dealt with to speed up a neodymium salt, such as neodymium oxalate or neodymium carbonate. The last action is calcination. In this high-temperature home heating process, the neodymium salt breaks down, repeling other aspects and and leaving the steady, high-purity Neodymium Oxide Powder (Nd2O3). The worldwide management in this detailed refining procedger is held by China Neodymium Oxide facilities, which have refined these techiniques on an industrial range.

Trick Industrial Applications of Neodymium Oxide.

The distinct digital and optical homes of neodymium ions, originated from Nd2O3, enable its use across several sophisticated markets. Each application leverages a specific characteristic of the component.

1. High-Strength Permanent Magnets . This is probably the most substantial application. Neodymium Oxide Powder is the main basic material for producing neodymium metal. This metal is then alloyed with iron and boron to produce Neodymium-Iron-Boron (NdFeB) magnets. These are the strongest type of irreversible magnets readily offered. Industries use them in electric car (EV) electric motors, wind turbine generators, customer electronics like smart devices and headphones, and clinical MRI machines. The toughness of these magnets enables severe miniaturization and effectiveness in electronic gadgets.

2. Advanced Glass and Ceramics . Manufacturers include Nd2O3 to glass thaws as a potent colorant. It conveys an attractive dichroic top quality to the glass, suggesting the glass modifications shade from a reddish-purple to a blue or green relying on the lighting problems. This impact is very treasured in ornamental glassware and art. Beyond aesthetic appeals, it offers a useful objective in optical filters and welding safety glasses, where it selectively absorbs yellow and green light. In specialty laser applications, neodymium ions are doped into host crystals like YTtrium Aluminum Garnet (YAG) to produce Nd: YAG lasers, which are important for commercial cutting, welding, and clinical treatments.

3. Catalysis . In the chemical market, Neodymium Oxide acts as an extremely efficient catalyst. Its surface residential properties can increase details chain reaction, boosting effectiveness and return. As an example, it locates use in petroleum breaking catalysts to refine petroleum right into gas. It is likewise a part in some vehicle catalytic converters to assist neutralize harmful exhaust gases. Its high thermal stability allows it to work effectively under the extreme temperature level problems located in these processes.

Below is a table summing up the primary applications for this flexible powder.

| Application ARea | Main Feature of Nd2O3 | Regular Purity Demand | End Products |

|---|---|---|---|

| Permanent Magnets | Forerunner for Neodymium metal (Nd) | > 99.5% | NdFeB magnets for EVs, turbines, electronic devices |

| Glass & Colorants | Offers dichroic coloration (purple/blue) | 99% – 99.9% | Art glass, welding safety glasses, optical filters |

| Laser Systems | Resource of Nd FIVE ⁺ ions for light boosting | > 99.99% (High Pureness) | Nd: YAG and Nd: Glass laser crystals |

| CEramics | Boosts thermal security and shade | 99% – 99.5% | High-temperature ceramic glazes, capacitors |

| Catalysis | Advertises chain reactions | Varies (typically 99%) | Oil refining, automotive stimulants |

Sourcing Wholesale Neodymium Oxide Powder.

For companies that count on this product, securing a secure supply of WHolesale Neodymium Oxide Powder is an essential functional job. The international market is characterized by a supply chain greatly focused in Asia. When sourcing the material, purchasers have to take into consideration a number of essential variables.

Initially, pureness is paramount. Purity degrees are normally used in qualities like 99%, 99.5%, 99.9% (3N), 99.99% (4N), and also 99.999% (5N). The needed purity depends directly on the application; as an example, high-performance laser crystals demand 4N or 5N pureness, while common glass pigmentation may only call for 99%.

Second, purchasers should specify the fragment size circulation (PSD). The physical kind of the powder effects how it blends and responds in producing procedures. Providers can offer powders with different ordinary particle sizes to meet particular industrial requirements.

Lastly, provider reliability is vital. Offered the marketplace concentration, partnering with recognized producers, specifically those in the China Neodymium Oxide market, makes sure constant top quality and supply chain stability. These vendors often give extensive certifications of analysis (COA) that information the exact chemical structure and physical properties of each batch.

Final thought.

Neodymium Oxide (Nd2O3) is much more than a basic chemical substance; it is a fundamental enabler of contemporary innovation. From the effective pressures generated by NdFeB magnets to the specific light of industrial lasers, its influence is substantial. The production of high-quality Neodymium Oxide Powder needs innovative refining procedures, an area where Chinese producers have developed a dominant position. As technology continues in green energy, electronics, and progressed materials, the critical relevance of Wholesale Neodymium Oxide Powder will just increase, strengthening its duty as an essencial part of the 21st-century industrial landscape.